Galvanized steel plates are divided into ordinary electrolytic plates and fingerprint resistant electrolytic plates. Fingerprint resistant board is an additional fingerprint resistant treatment added to ordinary electrolytic board, which can resist sweat and is generally used on parts without any treatment. The brand is SECC-N. There are two types of ordinary electrolytic plates: phosphating plate and passivation plate. Phosphating is commonly used and the brand is SECC-P, commonly known as P material. There are two types of passivation plates: coated with oil and not coated with oil.

Main features:

Corrosion resistance, painting resistance, formability, and spot welding resistance.

It is widely used, mainly for components that require a good appearance in small household appliances. However, compared to SECC, it is more expensive, so many manufacturers switch to SECC to save costs.

Divided by zinc: The size of zinc flakes and the thickness of the zinc layer can indicate the quality of galvanizing, with smaller and thicker being better. Manufacturers can also increase fingerprint resistance processing. Also, it can be distinguished by its coating, for example, Z12 represents the total amount of double-sided coating of 120g/mm.

For example:

Aluminum zinc coated steel plate (SGLD): It is a multiphase alloy material that contains both aluminum and zinc rich materials. Due to the characteristics of aluminum and zinc, it has better performance than hot-dip galvanized steel plate (SGCC). Main characteristics: corrosion resistance, with much higher ability than SGCC; Heat resistance; Thermal conductivity and thermal reflexivity; Formability; Weldability. Usage: Used in areas that require good reflectivity, such as reflective plates inside ovens and reflective plates in electric cookers. Hot dip galvanized steel plate (SGCC) is commonly used, aluminum zinc coated steel plate (SGLD) is deep stamped, and SGCE is ultra deep stamped.

Quality inspection standards

The quality requirements for high-quality galvanized sheet include specifications, dimensions, surface, galvanizing amount, chemical composition, sheet shape, machine function, and packaging.

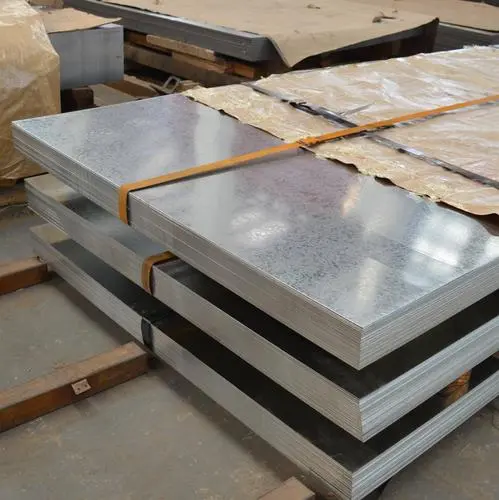

1. Packaging

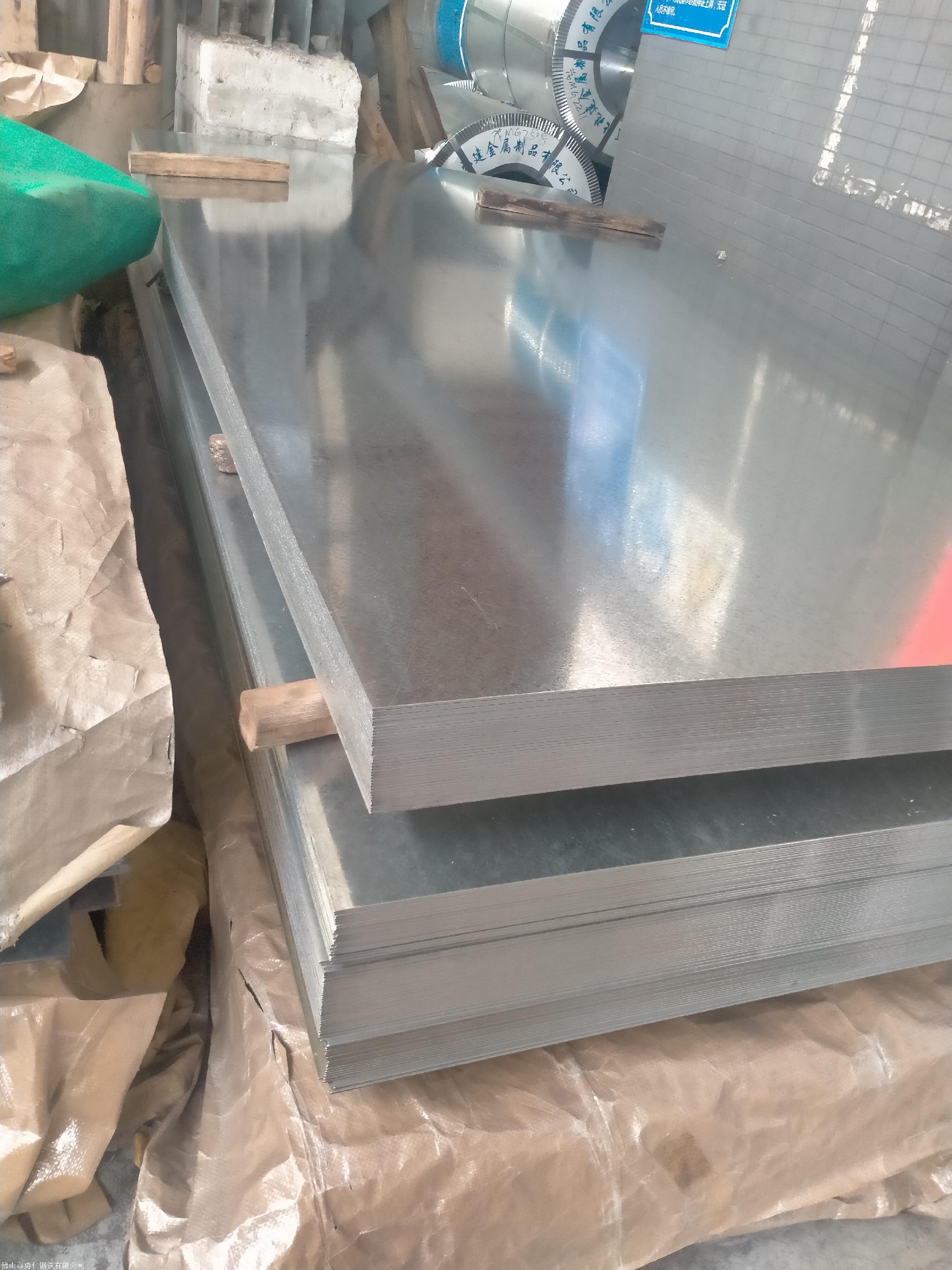

There are two types of packaging: galvanized sheet cut into fixed lengths and galvanized sheet with coils. General iron sheet packaging, lined with moisture-proof paper, tied with an iron waist outside, securely fastened to prevent friction between the galvanized plates inside.

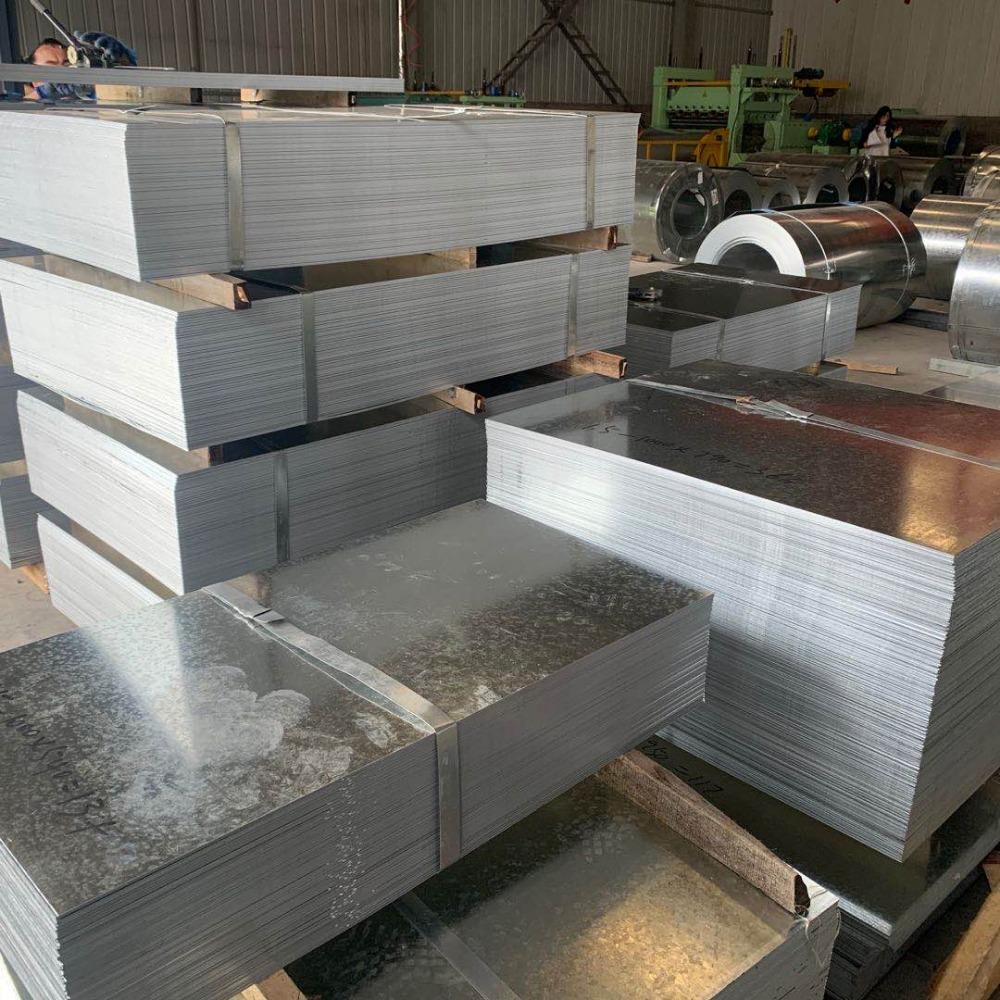

2. Specifications and dimensions

The recommended dimensions, thickness, length, and width of the galvanized sheet, as well as their allowable defects, are listed for the product scale (such as the following and). In addition, the width and length of the board, as well as the width of the roll, can also be determined according to user requests.

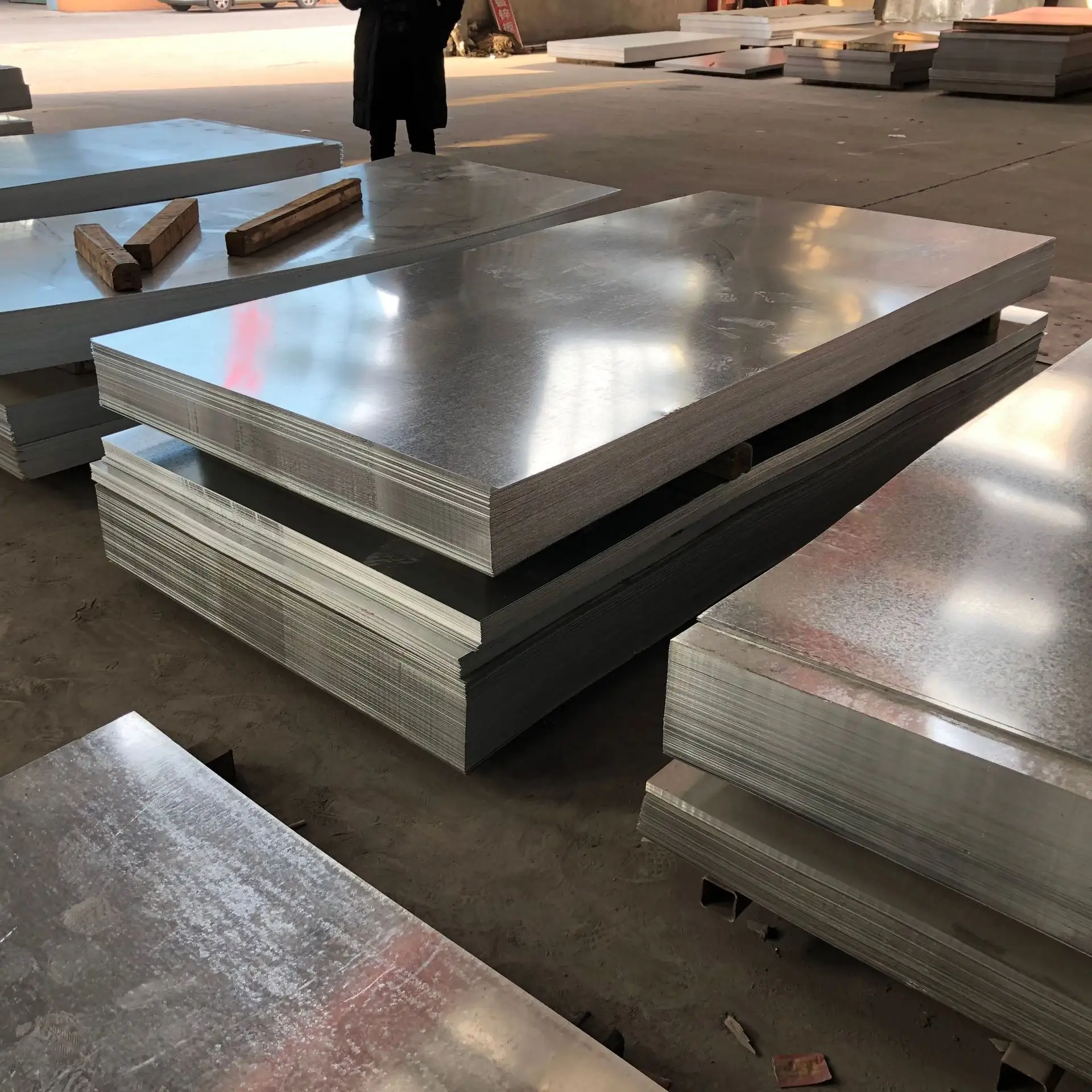

3. Surface

Overview: Due to different disposal methods in the coating process, the overview of galvanized sheet is also different, such as the overview of ordinary zinc flakes, fine zinc flakes, flat zinc flakes, zinc free flakes, and phosphating treatment. Galvanized sheets and galvanized coils cut to a fixed length shall not have any defects that affect their use, but the coils shall allow for less deformed parts such as welding parts.

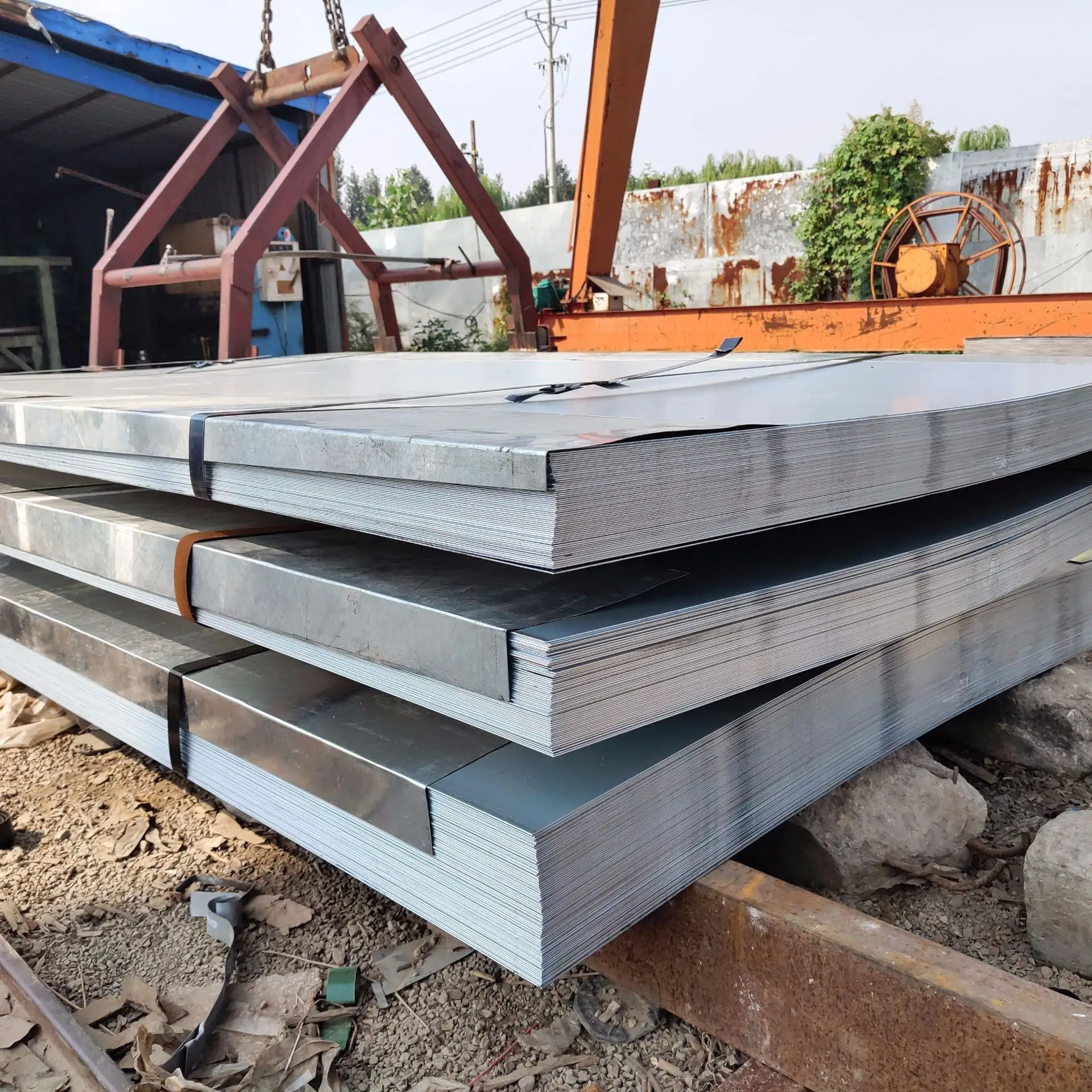

4. Galvanizing quantity

Scale value of galvanizing quantity: Measuring galvanizing quantity is a widely adopted method for determining the thickness of the zinc layer on galvanized sheets. There are two types of galvanizing: equal thickness galvanizing on both sides and unequal thickness galvanizing on both sides. The unit of galvanizing quantity is g/m2.

5. Machine functions

(1) Tensile test: Generally speaking, galvanized sheets for layout, stretching, and deep stretching have tensile performance requirements.

(2) Bending experiment: It is an important term for balancing the process function of thin plates. But the requirements for various types of galvanized sheets vary among countries around the world. The general requirement is that after the galvanized sheet is bent for 180 degrees, there should be no zinc layer left on the outer coating,