While ensuring quality, we continue to reduce management costs and improve management efficiency. We are the first in the industry to adopt a national unified quotation and publicly disclose the cost calculation formula for ordering orders, greatly benefiting our partners and users.

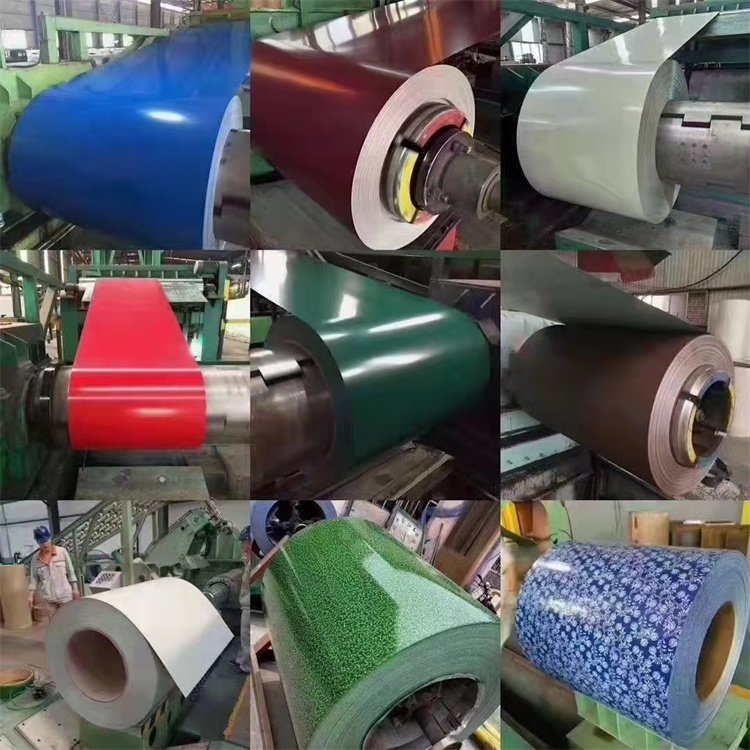

All products of Jiaxiang are made of imported materials and can be designed and processed according to customer needs. After long-term efforts, the company has developed a certain sales scale in various countries, and its products are constantly updated, deeply welcomed by customers.

Our products are customized according to on-site dimensions. The factory provides personalized and customized services, selecting high-quality raw materials, and producing products according to standards. At the same time, we are dedicated to product production and sales to ensure continuous new product development capabilities.

Jiaxiang supports customized special specifications to undertake fixed length processing, with sufficient raw materials, short construction period, and a complete stock supply of 2000 tons of specifications

TEL:15106884444

Mailbox

A steel pipe without joints along its cross-sectional perimeter. According to different production methods, they are divided into hot-rolled pipes, cold-rolled pipes, cold-drawn pipes, extruded pipes, and top pipes, all with their own process regulations.

It is best to control the air pressure of the spraying equipment used for the renovation of the colored steel tile roof at 5-6 kgf/cm2. If the pressure is too low, the paint atomization will be poor, and the surface will form pits; Excessive flow can cause sagging and excessive paint mist, which not only wastes materials but also affects the health of operators.

What should be paid attention to when using paint on color coated boards: 1. Primer epoxy primer (amino cross-linked type, polyurethane cross-linked type, epoxy phosphate ester type); Modified epoxy primer (polyurethane modification, polyester modification, polyamide modification, etc.); Polyester primer (amino cross-linked, polyurethane cross-linked); Waterborne primer (water-based electrophoretic paint, acrylic emulsion primer). 2. Back paint epoxy type (same as epoxy type primer); Polyester type (amino polyester, epoxy modified polyester); Amino alkyd type; Polyurethane. 3. Vinyl coil topcoat; Plastisol and organic sol (polyvinyl chloride); Polyester type (amino type can be divided into flexible 0-1T and hard 2-3T, while polyurethane type can be divided into TDI type and HDI type); Silicone modified polyester (hot splicing: organic silicon content 25% -50%; cold splicing: organic silicon content less than 30%); Acrylic acid (thermosetting, in which solvent based self crosslinking coatings are prepared from copolymerized resins with alkylated methoxyacrylamide, used on pre treated aluminum without the need for primer; water-based water-based acrylic coatings are used with amino resin as crosslinking agent); Weldable type (using zinc powder, or water-based baking paint composed of chromic acid, zinc powder, and other chemical crystals without resin, or weldable zinc rich coatings containing a large amount of fine particle zinc powder using linear epoxy resin as the base material); Fluorocarbon resin type (the main variety is a dispersed coating mainly made of polyvinylidene fluoride resin, with a fluorocarbon resin content of at least 70% of the total resin content and a solid content of at least 40

Copyright ©2023 Liaocheng Jiaxiang Steel Pipe Co., Ltd